A Design For All Seasons

This amp was designed and built with several different goals in mind. The first was that I needed a small amp for my work/listening area. This is a small space, about 8’ x 10’, so I didn’t really need lots of power. I thought that a nice single ended UL 6V6 design should be just about right.

The second goal was to test a hypothesis. I had been seeing lots of talk on the tube forums about “heater hum” and how DC heaters supplies were required and that heaters should always be “lifted” above the potential of the cathode. Now there is much truth to this when using tubes with directly heated cathodes, but with unipotential cathode tubes (i.e. tubes with a cathode electrode separate from the heater) the isolation between heater and cathode should be sufficient to prevent audible hum. My hypothesis was that the hum problems people were discussing arose mostly from B+ ripple and poor lead dressing inside the chassis. So I would design a power supply with B+ ripple below the limit of my test equipment, apply proper build techniques and see how I did.

Lastly, I wanted this amp to have just a little bit different visual aesthetic. So often all the attention goes into the electronics and little into the look of the amp. I wanted to avoid that trap. So I decided to use a nice piece of Australian lace wood for the base and I chose a black and brushed silver accent theme.

Overall I think the design worked out quite nicely.

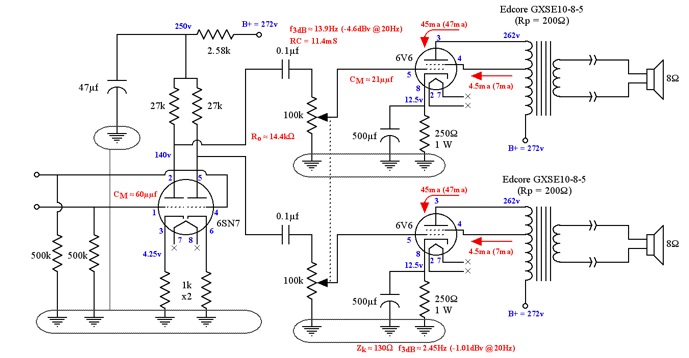

The Electrical Design

As I said in the introduction, I decided that I wanted to go with a single ended 6V6 design run in ultra linear mode. To do this I simply took the design point for a single ended class A stage directly off the 6V6 data sheet. This called for a -12.5v bias, a 250v plate and screen voltage, and a 5kΩ plate load. I then chose an Edcor output transformer that had a UL tap, calculated a resistor for cathode bias, and my preliminary output stage design was done. Now what about the driver?

I only needed 12.5v peak to drive this output stage. I also wanted a good performer sonically. So I decided to use a 6SN7. With it’s low µ and very low noise it fits the needs for this driver very well. The 6V6 family (6V6, 7408, 6AQ5, 6005, etc.) can be a little cool in the UL mode and I wanted to preserve some warmth as this amp will be used mostly for soft jazz and light classical music. As such, I decided to use a fairly small plate load on the 6SN7. This preserves some of the 2nd order harmonics and keeps the sound both warm and very smooth. Here is my load line for the driver stage.

I decided that the unbypassed cathode gain of -8 was just about perfect. This means that I only need a little over 1.5v peak (1.1v RMS) input to fully drive the amp. This is well within the capabilities of most line level outputs, iPods, CD player, etc. Also, the -4.25v bias point of the input stage means that the probability of every overdriving the input stage is very low.

I decided to put the volume control after the input stage to minimize it’s effects on amplifier noise figure. This led to the following schematic for the amplifier.

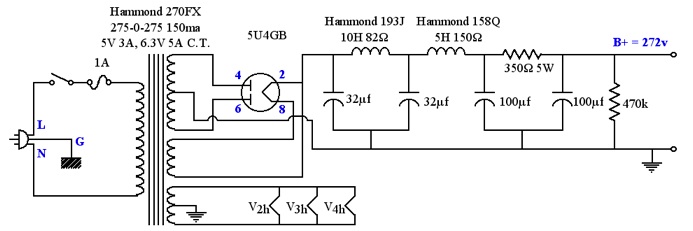

Now it was time to worry about the power supply. As I said, I wanted a very quiet B+ supply. I also wanted to use tube rectification so that I could avoid using a “standby” switch. This necessitated adding an additional stage of LC filtering to the supply as well as additional filtering for the driver stage. (This is the 2.58K / 47µf pair in the schematic above.) Here is the resultant power supply schematic.

My goal for the supply was less than -90dBv ripple at the inputs to the power stage. This equates to ≈ 8.6mV at 272vdc. Ripple at the output of the rectifier is approximately 5.5v so my filter section needed a ripple reduction factor of approximately 640.

The primary ripple frequency into the filter is 120Hz. As a rule of thumb, for any series-shunt LC pair, if the reactance of inductor is greater than about 20 times the capacitor reactance, then the filter stages can be treated separately. This is clearly the case here. For the first stage, the ripple reduction factor is ~181. This puts the ripple at the output of the first filter stage at 30.4mV. The ripple reduction factor for the second filter stage is 283 for a total ripple output of 0.1mV. But the voltage was still too high at this point and a dropping resistor was required. Here the resultant RC filter stage has a ripple reduction factor of 27.4 resulting in a final ripple into the power stage of ≈ 7.5µv (for a total ripple level of -171dBv @ 272vdc). Clearly this B+ supply will not be introducing any extraneous hum into the audio path. The additional RC pair on the driver stage supply gives an additional ripple reduction factor of 92 giving a theoretical ripple voltage of 81nV at 250vdc.

Obviously these theoretically small ripple voltages are not realized in the actual circuit. But the values are small enough to virtually guarantee no B+ induced hum on the audio outputs. Now with the electrical design complete, it was time to turn to the layout.

The Prototype

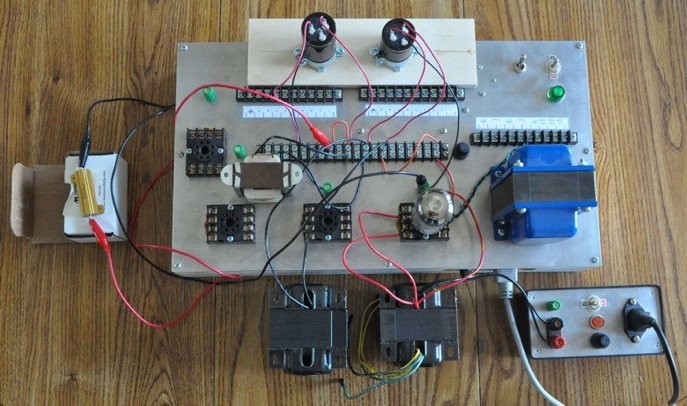

I had already done a fair amount with the 6SN7 and the 6V6 design point came off the data sheet so I didn’t feel like I really needed to prototype the amplifier circuit itself. The power supply on the other hand was something I really needed to test out.

I needed to confirm that I could get the very low ripple numbers I needed from my design. So parts in hand, I turned to my prototyping station and went to work. Below is a picture of the entire power supply connected to a 2kΩ load resistor.

The only thing omitted from this prototype is the 470kΩ bleeder resistor and the 5v filament supply for the 5U4GB is coming from the prototyping station. The total ripple measured at the resistor in this setup was about 100µV or -128dBv. Not quite the -171dBv calculated above but quite remarkable for a prototype of this nature. In fact, so remarkable that I checked the reading several times. It was however VERY sensitive to lead placement.

So my power supply design was good. Time to layout the amplifier.

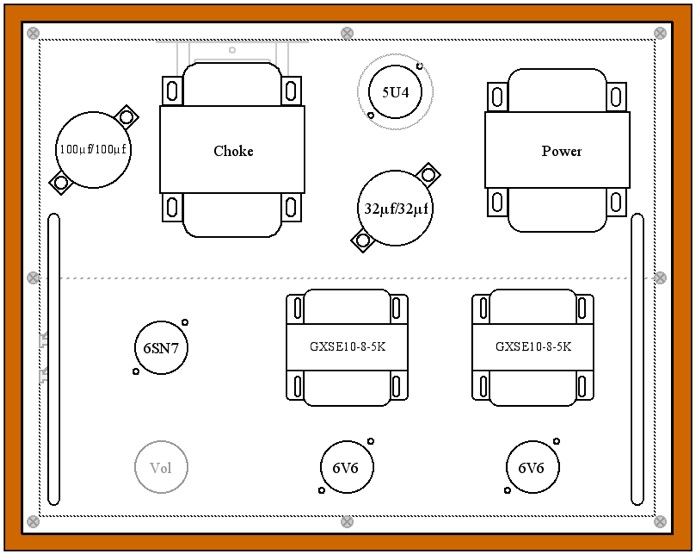

The Layout

It took a while playing with all the components to arrive at an acceptable layout. The top plate of the chassis would carry the major components with the point to point wiring underneath. The only compromise on this decision was to place the 5H power supply choke inside the chassis. This was done for two reasons; one, putting it on the top plate resulted in a much larger build and, two, I decided to use an open frame choke I had on hand so for aesthetic reasons I wanted to hide it. Here is the layout for the top plate showing all the major component locations.

This layout has several advantages over the others I tried. First, it places the power transformer and the rectifier tube as far as possible from the main driver tube. This minimizes interaction there. It also puts the driver tube close to the last power supply filter stage. This minimizes the possibility of additional hum being induced in the run from supply to driver. You’ll also notice the dashed gray line across the center of the amp. This represents a metal shield between the power supply and audio sections of the amplifier. This is to help minimize any interactions inside the amplifier.

The Build

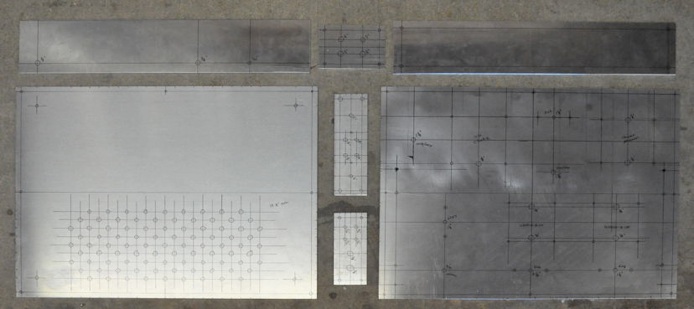

In addition to wanting this amp to look good, I also really wanted this amp to be quiet and fairly well shielded. Since I had already decided that the base would be lacewood, this meant lots of metal. In addition to the top plate and base plate, it has a metal divider, a hum shield inside the front wall, metal plates for the inputs and outputs, and a metal mounting plate for the AC power input, fuse, and switch. This translated to a large amount of 80mil 6061-T6 aluminum plate. Here are all the aluminum plates cut and marked for drilling.

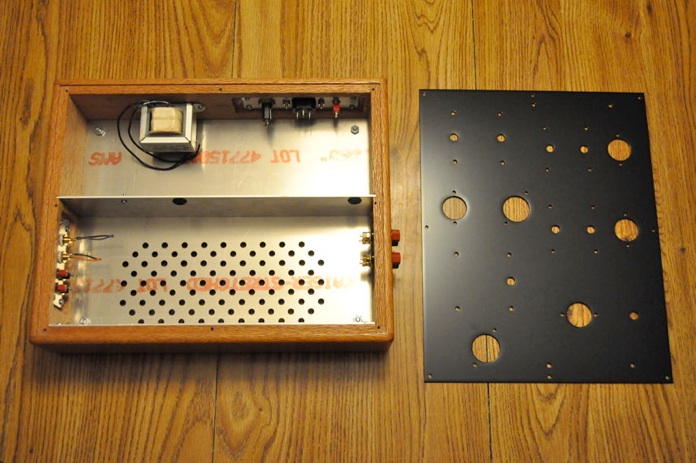

Once drilled, painted, and installed on the wood chassis it was time to actually start the build. Here is a picture of all the smaller metal pieces installed on the chassis.

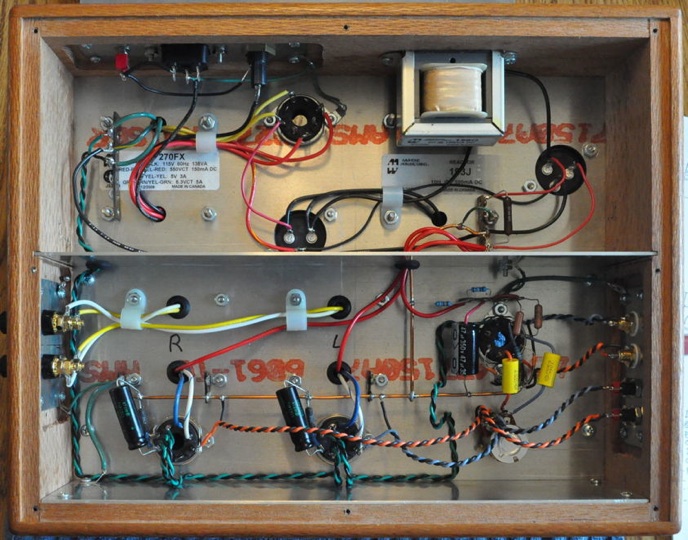

To assemble the amp, the top plate was secured in place so that the wiring could be accomplished from below. With the top plate installed all the major components were mounted. Here is a picture from the underside.

From this point, assembly was fairly straight forward. Just follow the schematics and do the wiring point to point. Every metal plate in the chassis has a point to tie all the parts together. This ensures a continuous electrical shield. The signal ground for the amp is tied to the chassis ground at only one point to avoid ground loops. Here is the finished wiring.

There are several features that help make this amp work well. The first is the bare copper wire ground bus. This serves as the main signal ground for the amp and connects to the power supply behind the shield. By tying all signal grounds to this bus, it helps to prevent ground loops. The second feature is the filament wiring. This is solid 20 AWG twisted pair that is very carefully laid out. Note how it follows the corners of the chassis whenever possible and when it feeds the sockets it actually loops up and comes down on the socket. This places it largely near perpendicular to the other socket wires helping to minimize interactions. Third, the signal inputs and the interstage signals are carried by twisted pair wring. Again, this helps to minimize interactions.

The Test

With the amp all wired up it was time for some testing. It turned out even better than I thought it would. First, the amp is dead quiet. With my iPod connected and paused, at full volume I could not detect any audible hum on the output. An oscilloscope hooked across the speaker terminals confirmed this as well. The amp produces 3.2W at full power into an 8Ω load. This is about three quarters of a dB below the data sheet number for the pentode wiring, but I expected a little loss when going to UL mode.

The amp was designed for flat response from 20Hz to 20kHz (even thought my hearing is nowhere hear that good anymore) but the Edcor output transformers are only rated down to 40Hz. They are still very clean at 20Hz but the signal rolls off below 40Hz and is about 4.5dB down at 20Hz.

Impressions

I think this amp was a success for me on several different levels.

First, the amp sounds great. Whether playing soft jazz, swing, classical, opera, or blues, it all sounds excellent. The amp sits in my work area and is alternatively fed by my computer, my iPod, or my portable CD player all with great results. This is exactly what I wanted for this space.

Second, the aesthetics of the amp work well. It is still traditional and understated in design, but the materials and theme work well together. The black and brushed silver create a nice feel and the lacewood is definitely something out of the ordinary. Here is a close up of one corner of the amp showing how it all comes together.

Lastly, I think I have sufficient evidence to support my hypothesis that AC heater supplies on unipotential cathode tubes do not induce hum in the audio chain. This amp uses 6.3 volt AC heaters with the transformer winding center tap tied directly to the single point ground. If there was going to be any interaction between the signal path and the heaters, I would have heard it in this amp.

Conclusion

This is a success. It looks good, it sounds good, and if does exactly what it was intended to do. With several hundred hours of listening now behind me I find myself liking this amp more and more each time I listen to it. I’m finding things in old familiar music that I never knew were there and I find myself exploring new music with ever greater enthusiasm. I couldn’t ask for more from an amplifier; nor anything I’ve built with my own hands.

As a follow up: This was my first amplifier built prior to the launch of this website. It was used for several years in my office as the amplifier I listened to most of the time. However, in March of 2016 I performed an investigation of 6V6 bias points and performance. After contemplating the results for quite some time I decided to use the newfound information to rewire this amp. The results were very good. The new lacewood build is documented in the 6V6 Lacewood Amp V2.0 page. You can build either amp, but you should read about them both.

Hello from England. Firstly, thanks for the website and the various amp designs, really appreciate the designs and all the info.

I have built the lacewood V1 exactly as specified with the exception of using the 370 series transformer for UK voltage and also Edcor 15-8-5 OP transformers rather than 10w as I had them from a different project. I also used 470uF bypass caps on the 6v6 cathodes, again because I already had them. Other than that it is exactly as you specified.

The amp sounds really good at low and mid frequencies – but is rather harsh at the higher frequencies, with quite a bit of sibilance and sounds a bit distorted at the higher frequencies ??

I wondered if you had any suggestions on why that might be or what changes might address it ? I have already tried some tube rolling with different makes of 6v6 and 6sn7’s which didn’t make any difference really.

Readings as follows – both channels are identical.

B+ = 250

6V6 plate = 240

6v6 cathode = 14.3

6sn7 plate = 129

6sn7 cathode = 3.7

I notice you don’t have cathode bypass caps on the 6sn7 (unlike the Lacewood V2 design) ? Also – out of curiosity, what might be the best way of altering the power supply so I don’t have to use the 193J 10H choke on the top of the unit (its rather bulky and I would like to free up space on top).

Many thanks for any suggestions (if you are still responding to the thread).

The most common reason for this behavior in the Lacewood V1 design is momentary overdrive of the driver stage. The easiest way to correct the situation is to move the volume control to the input side of the driver stage like it is in the V2 topology. This way you’ll have more control over the driver voltage and be able to control the overdrive.

Many thanks Matt. I have done that now…..but it hasnt made any difference really. Just so you know….I actually built V2 in its entirety, but had the same problem. So I reverted to V1…..with the pot at the front now I have also attenuated the input (approx 20db) but the problem persists. I am struggling to think what it might be ? I have tripled checked all the wiring. The amp is virtually silent by the way….no hum at all. I know the power supply is rock solid.

Thanks for the choke suggestion…..I will get an order in for the 6H. For some reason its much easier to get it sourced form the USA rather than here in England. In fact I get most of my kit from the states.

All the best.

In this situation the problem is clearly systemic. And by “systemic” I mean within your specific environment. It is highly unlikely that two separate builds would fail to perform in exactly the same manner unless it was something overarching in construction or environment.

My first recommendation is to begin looking at common items, first in the amplifier itself, then in the environment; both physical and electrical. Does this happen in both channels or just one? Have you tried swapping tubes? Are you sure it’s the amplifier and not either the source, speakers, or wiring. I suggest changing all three, one at a time, and see if something changes. Also check your environment. Take the amplifier to a different venue, this can be another room, another house, or even outside. Check your mains supply for noise or bias problems. If all or this doesn’t help look at things closer to the amp itself. Sometimes volume controls can be an issue. Some are so low power that even an iPod can produce enough power to burn them out. One shot they are forever shot.

I realize that you have probably done a bunch of this already. I’m just trying to be thorough. But I am convinced that the issue must be systemic in some way. If you can’t solve this please email me directly and we can go over things in more detail one on one.

Good luck.

Hi Matt.

Thanks for your comments/help. I am fairly sure you are right. Sometimes its easy to overlook the obvious ? And so I have been experimenting…..and I think I may have found the issue ?! The source I was using were the analogue outputs from a rather old Logitech Squeezebox, playing either Radio Paradise or my own FLAC files off a Qnap NAS drive. So I changed the source to an old and very basic cd player…..and there was a marked improvement. So then I dug out a much better quality cd player from my stock cupboard, and hey presto, even more improvement. My conclusion thus far is that the squeezebox outputs are either faulty or just rubbish in the first place, and of course that the quality of the source signal is paramount. With a good quality cd player the amp really sings. I might try your Marblewood design now, I have a 12ax7 and other spare parts and I am interested to see how it might sound.

Thanks for all your help – much appreciated.

I’m glad you found the potential cause of the issue. I agree that not all sources produce great signals. I like my Cambridge AXC35, but my portable CD players, not so much.

Hi. I don’t want to interfere but I had the same issue. Highs distorted and saturated. My solution was easy, but took time. I had just swapped the transformer connections. The 40% secondary grid was on the wrong side. I just switched the 2 terminals of the transformer and the problem disappeared.

And as for the choke… the power supply filter in the V1 is over designed. You can replace the big 10H primary choke with a Triad C-14X 6H open frame choke under the hood and you’ll be fine.

Just an FYI, I don’t know if it makes any difference but I think I have read that the best practice is to mount the chokes at a 90-degree angle to the power transformer. Is that right do you know?

In the case of unshielded magnetics (i.e. those without quality end-bells) it is sometimes advantageous to rotate the units to reduce coupling. The requirement for his approach comes from using inexpensive and/or poorly constructed transformers and chokes. If your transformers and chokes use well fitting end-bells and are properly gapped, there is usually no reason to experiment with mounting orientations. I have never had a stray field coupling issue using either Hammond or Edcor shielded magnetics.

HI Mat,

I am Tomo from Australia. I have decided to build this amp according to your design. I have two questions: firstly, your design is for 60Hz if I am right; is any change needed in power supply to work from 50Hz mains? And secondly, in terms of sensitivity, what kind of speakers are you using with this amplifier? Does amplifier requires high sensitivity speakers for normal listening environment? Thank you.

The first part of your question is simple. So long as you select a power transformer that is wound for 50Hz, then the component values in the power supply are more than sufficient to produce a very quiet amplifier. For example, I used the Hammond 270FX transformer in this amplifier which is 120v@60Hz only. However, the Hammond 370FX has exactly the same outputs but is rated for both 50Hz and 60Hz and can be wired for many different mains voltages. Since the standard mains power in Australia is 230v@50Hz, this is the transformer I would recommend for your build.

The answer to your second question is “it depends”. The amplifier produces in the neighborhood of 3 W-rms / channel at full drive. The volume really depends on the room size, listener position, and speaker sensitivity. Theoretically, a speaker sensitivity of 90dB would yield approximately 98dB SPL at ≈1m in front of two speakers. But this isn’t the real story. For a more complete explanation I am going to have you read a blog post of mine from 2014 on sound pressure levels. The post is here: How Amp Technology Affects Volume and Power. This should answer your question. In most instances I recommend a speaker sensitivity of about 90dB/W but read the post first.

I also think you should read the post “Talking about SETs” from December last. Even though it is talking about SETs, the information on SPL levels applies to all in-home amplifiers.

Thank you so much for your reply, I will read posts that you have mentioned with interest. May I ask you if you would be able to send to my email scan of templates for metal work, it is very hard to read from picture on your site.

Thank you

I will be using Altec 515B and 420A speakers, I think it will be okay.

Check your email. 🙂

Hello from Italy.

Why not to use a 6SL7 in place of 6SN7?

The mu of 6SL7 is more hight than 6SN7.

Because the gain of the 6SL7 is too high for this design. With the 6V6’s biased at only 12.5v, the gain of the 6SL7 would have meant that, with a normal line lever input, the amp would have been overdriven at a very low volume setting. Too much gain is worse than not enough.

Hello!

From Italy.

Beatiful amplifer.

I have two 6V6 (1938) and 6SN7 and 6SL7.

I have a question.

Do you have to try with a record player?

I search a good tube amplifer fon only record player.

And the main problem is the low voltage out put of record player.

Thank you.

The issue you are having is likely due to the phonograph cartridge type. Magnetic cartridges (MM & MC) have relatively low outputs and need frequency equalization. This is usually provided by a dedicated phonograph preamp.

If you don’t mind a well designed SS solution, the Boozhound RIAA preamplifier is highly rated, relatively inexpensive as a kit, easy to build, and has really been wrung out DIY-ers. Here are some links:

https://boozhoundlabs.com/collections/all/products/bhl-audio-jfet-phono-preamplifier-kit-2sk170-riaa

http://diyaudioprojects.com/Solid/JFET-Phono-Preamplifier-Kit/

I recommend you read up on this solution and decide if it meets your needs.

I will try with a 6Q7 preamplifer, 6K7 second preamplifer and 6V6.

If this solution works, I will say to you.

With schematic, of course.

Hello!

I’ve been building guitar tube amps for a while now but want to start on my own audio amplifier soon. This looks like the perfect candidate as a starting point! Very elegantly done and also clearly laid out.

One question I have though is about the inputs. The main line level input clearly goes just straight to the grid of V1 but I also noticed two other inputs going straight to the powertubes. Is this to supply a direct in to the poweramp from another pre-amp?

Regards, Marijn

These were actually test points to monitor the power stage drive. If you look at the Lacewood V2.0 (which uses the same chassis as the original) you can see I disconnected them. I used the inputs to study how the power stages behaved as they started to move into overdrive (i.e. grid conduction). As they were not required when I had finished my investigation, I removed them in the V2.0 version.

By the way, if you plan on building the Lacewood amp I strongly suggest the V2.0 version. Overall it is a better amp (in my humble opinion).

Thank you for the quick reply Matt, I will definitely take a look… Google directed me straight here and I haven’t looked around any further yet.

Hi Matt. Thanks for the great design. I have a pair of the original Klipsch Forte’s and I’ve been looking for an amp to build to go with them. Yours looks perfect! One question though: do you think the higher spec Edcor CXSE output transformers would be a good upgrade, or would they make little difference? They increase the cost quite a bit, but the Fortes have pretty deep bass extension, so I thought they might be worth it. What do you think?

Thanks!

Pat:

The Klipsch Fortes definitely are a good match for the Lacewood with their high sensitivity (SPL 98dB/W) and frequency range (32Hz-20kHz). A couple of points. First off, I strongly recommend the Lacewood V2.0 schematic over the original. It overall is a better audio design and my comments will be in reference to that design. My build of this amp uses the Edcor GXSE10-5K outputs transformers and this is the limiting factor in the bass produced by the amp. Whereas I still consider the bass in the Lacewood more than sufficient for most music, it is down about 3dB at 40Hz and about 4.7dB at 30Hz.

Now the main driver of bass response is the effective plate resistance of the tube and the primary inductance of the output transformer. There isn’t much we can do about the tube but we can choose different output transformers. The primary inductance of the GXSE10-5K is only about 5H. This is not much and it is what accounts for the low end performance of the original design. Now the CXSE25-5K has a massive primary inductance of 50H. This is high enough to give really full bass extension well below 20Hz. But the transformer is large and expensive ($94 USD and 9.75 lbs.). An intermediate solution would be the GXSE15-5K. This transformer is $50 USD and 2.75 lbs. (I thing saving $88 USD and 12 lbs. is something at least worth considering. 🙂 ) And whereas Brian has not published the primary inductance of this particular transformer, my experience is that it has enough inductance to really help fill out the low end on these SE-UL amplifiers. My only concern with the CXSE25-5K is that the large primary inductance will suppress the really excellent transient performance of the amplifier. See my article here on this issue: “A Consequence of The Quest for 20Hz Roll Off”

So I guess my recommendation is to use the GXSE15-5K to help fill out the low end but to be careful of going with a transformer having a very large primary inductance. I hope this helps.

Matt

Thanks! That’s very helpful. It’s going to be a balance between bass extension and transient response, then. I value fast transient response – I feel that’s a big part of what makes live music so “live”. Thanks for the detailed explanation!

I bought a prototype amplifier using 4 5u4 rectifier tubes 8 6l6 tubes and no other voltage amplification it uses two power transformers and 2 audio transformers I have not powered it up as I know it is going to need a higher input power than usual Like 6 volts p to p, I want to get it going but it is wired in stereo and I think it is wired in push pull class A stereo should I use 2 6c5 tubes for each channel like they do in the rca 4228 amplifiers?

Without a schematic or at least a more complete description I cannot answer your questions. Four big rectifiers and eight 6L6s seems like a strange combination. Perhaps you could post over at the DIYAudioProjects forum and let people chime in.

Hi,

came across this design and want to build.

Question… are all resistors 1/4w unless otherwise indicated? and what are capacitor values for volts?

In general I use all 1/2W metal film resistors as s a standard. The exception in this design is the cathode resistors on the 6V6 tubes (1W) and the voltage dropping resistor 350Ω, 5W in the power supply. Capacitor voltages vary. The power supply filter capacitors all need to be rated at at least 400vdc. The same applies to the 47µf filter capacitors on the driver stage. The 0.1µf coupling capacitors likewise need to be rated at a minimum of 400vdc. The bypass capacitors on the power stages just need to be rated comfortably above the bias voltage. I like to use a minimum of 25vdc ratings here and sometimes I’ll go as high as 50vdc if the capacitors aren’t too large.

Thanks Matt… much appreciated. Will be ordering parts to begin project. Yippie!

Hi Matt,

I would like to build the Lacewood Amp. I am trying to do it on a budget and with parts I have on hand. My idea is to build it and if it works then I will try to substitute better parts into the amp. I have most of the bits but my transformer is the Hammond 240-0-240 with 6.3 and 5 volts. Do you think I could get away with this lower voltage.

Thank you

I think you’ll be fine. The B+ can be adjusted upward by lower ing the value of the dropping resistor or by substitution of the rectifier.

Hi Matt

the lacewood you refer it looks a lot like the wood that was used as window frames in a 1950s house I had. I was told it was commonly used for this purpose as well as for furniture and clothes cabinets before pine and chipboard became the norm. if the same wood it comes from a tree named the Sily Oak (Grevillia robusta) in Brisbane Australia and there are quite a few trees growing in my neighbourhood likely planted by the local Council. I have never seen them growing in a native forest although supposedly it’s widespread including in many other planting’s in other countries. Some details about this tree attached if of interest. http://bie.ala.org.au/species/http://id.biodiversity.org.au/node/apni/2918082

Yes. There are several species that are very similar. I think in my posting I said that this was Australian Lacewood (i.e. “Northern Silky Oak”, Cardwellia sublimis) but after examining the wood more closely I believe it to actually be Brazilian Lacewood (Panopsis spp. {P. rubescens and P. sessilifolia}).

There are several woods that get confused and sold under various names depending on where you’re located. There is Brazillian Lacewood (Panopsis spp. {P. rubescens and P. sessilifolia}), Leopardwood (Roupala montana {syn. R. brasiliense}), Northern Silky Oak (Cardwellia sublimis), and Southern Silky Oak (Grevillea robusta). The first two being South American species and the last two being Australian species.

I’ve been a woodworker for almost 30 years and I still get these species confused sometimes when looking at them in my shop.

hi Matt

Does this amplifier build come with a parts list? also in australia the electricity is supplied at 240v. can you advise how might this change any values that need to be observed.

The only real change you’ll have to make is the power transformer. Instead of the Hammond 270FX as shown in the writeup, you’ll have to use the Hammond 370FX which has the same secondaries but a “universal” set of primary windings that can be configured for a number of different line voltages.

Hi Matt:

I’ve been reading your results for both versions and I think I want to try experimenting with SE like you have here.

My audio input will be from a Sansa Clip+ Mp3 player which is not “line level” but less.

So I think that instead of the 6sn7 I might need the increased gain of the 6sL7 and if so what would you suggest for bias settings and parts values for 6sL7?

I also thought to use 6sh7 pentode to drive the 6V6s. My initial bench tests indicate sufficient drive. But do you feel the 6sL7 triodes will have better audio performance quality over the pentode?

BTW:

I currently use a great little 6V6 PP integrated amp using the op275 J-fet opamp to drive the 6V6s in class AB with about 20v bias @ 25ma idle current from an LM317 CCS.

I don’t have your sophisticated measuring equipment so I don’t know if my audio quality compares to what you describe … so for fun this week I will try to build your VER2 amp w/18.1v bias @ 46ma

(I just bought the same SE OTs from Edcor you are using)

I wonder what your opinion is for me to stick with the op275 or opa604 to drive the 6V6 in SE …or do you feel I’d get best results from the 6sL7 triode or 6sh7 pentode?

My power supply design currently should be sufficient for the SE 6V6 version since it has only 20mv of ripple at 295v DC.

here’s my current PP 6v6 schematic using the op-275 drivers:

http://pbpix.com/amp/6v6%20pp%20amp%20change%20hw.png

I’d appreciate your feed back Matt.

Thank you,

Peter

peter@pbpix.com or pbpix@optonline.net

Hey, I’m a huge fan of the way this looks and am wondering two things. One, what type of binding posts are you using, and two, those metal handles look great, where did you find those?

The handles are just Bar Pull Cabinet Handles like these here: Bar Pull Cabinet Handles I got them at my local hardware store but there are a lot available on the internet. And the binding posts are a dual 5 way biding post I got from Antique Electronic Supply. Here is the link: Binding Post – Dual, Gold-Plated

I hope this answers your questions.

Hello! Thanks for this project and great details! I’m thinking to build this one. My speakers have 98db of sensibility. Do you think I will get nice (mainly bass) response with this project?

This amp has a very good response for music. I suggest you use the V2 schematic as this uses optimized bias points and has a better soundstage. In general UL amps are a tradeoff between musical response and deep bass. For example, the V2 Lacewood amp has a -3dB frequency of almost exactly 40Hz. This is more than sufficient for almost all music. In addition, this amp has excellent transient response. This amp keeps up with the fastest scores I can find with no problems. But if you’re looking for rumbling bass for your home theater, this is not the amp you want. If you want an amp that tackles the toughest musical score with ease, this amp should make you very happy.

Matt,

I am about to start work on building a Lacewood amp. Is there any design for the power supply without using chokes. Also I would like to use solid state rectifiers. Will I have to make any changes in the PS filter design if I do so?

Sharat

There are two major changes to make in the power supply.

The first is to replace the 5U4GB with two good quality UF4007 rectifiers. Without chokes in the power supply to tame the high frequency noise, you really need to use UF series rectifiers. Do not skimp here. I recommend Vishay/Dale or Fairchild as the manufacturer.

Second, you’ll need to adjust the filtering. RC filter sections provide far less ripple reduction than LC sections. This means increasing the size of the capacitors after the first 32µf cap following the rectifiers. Don’t increase the size of the first capacitor or the conduction angle will get too small and cause transformer heating. You’ll likely need two RC sections to replace each LC section. Don’t worry about making the caps extra large. You’ll get far better filtering with more stages than with overly large capacitors. Manage the series resistance elements to get the output voltage around 270v-290v.

Hi Matt

Last question, what is the working voltage of the 6v6

cathode bias resistor… will 30 v do ?

Hi again Matt,

I just completed the Lacewood amp build, and am having a low output volume problem. I’m driving a pair of small Polk audio Monitor 30 speakers, and the amp input is an Ipad at max output level. I use this setup with another low wattage tube amp and it provides good strong volume, so I’m comfortable with this arrangement.

I did some basic voltage tests, and found the B+ is 20 volts low at the power supply, and subsequently throughout the amp. I assume that could cause a low volume condition. Any ideas why this voltage would be low? The only difference in my build from yours is I used a 330 ohm 5W resistor in the PS. Otherwise, I copied your build exactly. I did test the PS before I built the amp, and it was strong, well over 300 volts with no load.

Would appreciate any thoughts you might have on this problem.

Thanks for everything you do here, Ron

voltage

A 7% drop in B+ voltage should not be causing your problem.

The first step in diagnosing something like this is to gather all the basic operational data on the amp in question. So you need to record the following DC voltages with the amp powered up and with no audio input: 6SN7 bias voltages (i.e. cathode to ground, left and right), 6V6 bias voltages, 6SN7 plate voltages (i.e. plate to cathode, left and right), 6V6 plate voltages, 6v6 Screen voltages (i.e. screen to cathode, left and right). B+ at the output transformer primaries and the driver stage B+ across the 47µf filter capacitor. You should also verify that output transformers are wired correctly (Red = B+, Blue = Plate [pin 3], Blue/white = Screen [pin 4]). I know it sounds crazy, but I have systemetically wired circuits wrong more times than I can count.

Reply with your voltage readings and we’ll go from there.

Thanks for your help Matt. Before I give you the meter readings, I should explain that when I when I was reading B+ 20V low I was powering the amp from a variable iso and it was set a bit low, around 116 AC. The amp was plugged directly into house outlet (about 124V) for the following readings:

Driver bias – 3.93, 4.03

6V6 bias – 11.70, 10.56

Driver plate to K – 130, 127

L 6V6 Plate to K – 237.5

R 6V6 Plate to K – 239.8

B + at xformer primary – 259

B+ at 47 mf – 238.5

I checked the xformer wiring, and I took all measurements with no input. Ron

All your bias voltages look to be in acceptable ranges. Since you’ve confirmed the output transformer wiring, the next place to look is the 6V6 cathode bypass and the volume control wiring. I think to really help, I’m going to need some pictures. Why don’t we move this discussion over to the DIYAudioProjects support page for this project; located here: http://diyaudioprojects.com/Forum/viewtopic.php?f=9&t=3274

I’m sure we’ll be able to get to the bottom of your issue.

Hi Matt,

May I ask where you purchased the dual can electrolytics for this project? I’m having trouble locating them. Thanks, Ron

Actually “Antique Electronics Supply” stocks a full range of JJ capacitors. Just search for part numbers C-EC100X2-500 and C-EC32-32-500.

Hi Matt could I use a GZ37 tube as rectifier in place of the 5U4 tube in the 6V6 Lacewood amp, as I have many of these tubes

best regards

Laurie

Yes. You can use any of the comparable octal base rectifiers (5AR4, 5AS4, 5AU4, 5R4, 5T4, 5U4, 5V3, 5V4, or 5Y3). All will produce slightly different B+ voltages. Just be aware that going from a 5U4GB to the GZ34 will likely increase the B+ voltage by around 30v. This is ok so long as you don’t use the old metal can 6V6s or the shouldered 6V6 tubes. These have a B+ limit of 250v which will be exceeded. I routinely use different rectifiers in the Lacewood design when trying things out.

I was noticing the comment about hum. It has been my experience, from over 50 years of tube electronics, design and repair, that the 120 Hz hum is due to not having the choke tuned. By this I mean a capacitor usually between .1 a,d .15, in value, shunted across the first choke. In the older Thordarson literature they used to talk about this subject in detail and how to tune a choke. Thordarson had two service manuals where this was discussed in detail. These manuals were from the 40’s era.

The comment about using a specialized amplifier for use with headphones was right on topic and is the only way to go.

Hi Matt,

I really appreciate your thoughtful designs and excellent builds. This Lacewood amp is truly a showpiece.

I’m wondering if it’s possible to add a headphone jack to this amp, and how you would do that. My goal is to build this amp, and would like to include the ability for a headphone.

Thanks for what you do here, it is inspirational.

Ron

Ron;

Just adding a headphone jack is tricky in a tube amplifier. Due to the sensitivity of most headphones, you can’t tap off the power stage because the noise, inaudible in speakers, really comes through in the headphones. This usually means the taping off the signal driver and then employing an impedance matching stage like a cathode follower or a white follower.

My experience is that the separate headphone amplifier is really the way to go when working with tubes. Take a look at the Recovery Amp for a really fine sounding headphone amplifier.

Hi ,

I found your website while searching for info on how to reduce power supply noise. Did you ever put an oscilloscope on the output, and see if there is any hum visible? How about if you hook it up to a sensitive speaker, and put it directly beside your ear?

I am currently fighting a losing battle with a commercially made amplifier, trying to get rid of hum. Hum is coming from ground loops, poor layout, and inadequate filtering – basically everything you paid attention to. It was below the threshold of audibility with my Linn speakers, but with my new Klipsch La Scalas it is extremely (annoyingly) loud. My plan is to build an external power supply according to the best possible design principals, and connect it via an umbilical cord. I was planning to use DC heaters too, but you have convinced me otherwise.

Glad you like the site. I hope you find it helpful.

I actually use three methods to look for hum. One is the oscilloscope, the second is a Leader LM-185A high sensitivity AC millivolt meter, and the third is my ear with shorted inputs, max volume, and my ear against the speaker. Experience tells me that if there is any num, one of these three is going to show it. I don’t trust my ears alone because at my age my hearing is not what it used to be.

The hum I am chasing looks very weird to me, maybe it has a signature you are familiar with it. When you look at the oscilloscope trace of the amplifier output, there is a spike which appears at 120Hz. The spike is a sharp transient, and the rest of the waveform is entirely flat.I am wondering if this is something the power transformer is emitting as it charges the filter capacitors.

This is classic power supply hum. The primary ripple frequency out of a full-wave rectified power supply will be at two times the mains frequency. If f-mains = 60Hz then f-ripple = 120Hz. This is almost always due to a filter problem. This can mean a design issue such as inadequate filtering in the design, a component failure (usually a bad capacitor), or a construction problem such as cold solder joints in the filter section. Personally I would check each of these in reverse order (i.e. construction, then components, then design).

By the way, if it was transformer leakage, then it would be at the mains frequency and not at twice the mains frequency. Actually, hum from power transformer leakage is pretty rare in well made transformers.

Matt,

I regularly read diyaudio projects.com and I enjoy reading the build threads. I really like this 6v6 lacewood amp and I am thinking I will build it in the next 12 months.

2 questions

1. What is the size/dimensions of the top plate?

2. If you were to build this 6v6 amp again would you change anything in the power supply?

I have read through the build thread.

I have read through your article on power supply design.

I have read through the thread on tube rectifiers.

I have read through Mark’s 6v6 black lace build with a split power supply.

Would you still go with a hammond power transformer or consider an edcor?

Would you still go with the 5U4 rectifier tube?

Would you go with the split power supply or not?

Or any other changes?

Thanks for your time,

Todd

The top plate is 11″x14″. If I were to rebuild the amp there are a few changes I would make but, yes, one of them would be to use the very nice Edcor XPWR163 in place of the Hammond 270FX. I would also go with an Edcor main choke for an “all Edcor” build.

If you post your questions over on the DIY Audio Projects page 6V6-6SN7 Humless “Lacewood” Amp I can go into design details.

Looking forward to hearing from you.

Thank you for the great write up–you have a great site! I have several guitar amps under my belt and was looking for a simple amp that I could build for my office–this one looks like a perfect weekend build.

I have a PT on the shelf that is 150ma @ 550 v–an Edcor XPWR163 I had from another project. By my calcs, that should work, correct? I’m figuring 47ma max plate, 7 ma max screen for each 6V6 and 40ma max (20 x 2) for the 6SN7 (although I don’t think it will ever draw that much) …do you mind double checking me?

Also, do you recommend I just take the plunge and build the universal preamp while I’m at it? Based on your impressions, the two sound like a great combo.

Thanks!

Kevin

Your transformer should work fine. I would recommend building just the amp first. They when it’s complete, put together the preamp if you like. In my opinion, doing multiple projects at the same time is just an added frustration that can take away some of the enjoyment of doing the builds. Not to say that I don’t do just that fairly often, but that’s why I know.

Thanks for the feedback, Matt!

One other question: what is the purpose of the banana jacks next to the input jacks? I tried to trace the wires, but I can’t make it out from the picture…

Cheers,

Kevin

Don’t worry about those. The banana jacks are just some test outputs that I included in my build. They should be omitted.

I liked the 6v6 lacewood design so much i wanted to build my first amp from scratch from parts salvaged from a 1954 RCA victor black and white floor model tv. i used 6aq5 power tubes, it took some head scratching with the socket pins, although im still working on refining my power supply i had it working on first power up thanks for the inspiration you got me hooked on a new hobby and i have gained alot of knowledge about vintage electronics and i crave more knowledge on the subject.

Being 12 years your senior I too remember the tube amps and am curious to try to build one myself. My resume includes a great deal of interface in the manufacturing of electronics. 8 years as material manager with Cray Research and 15 years owner of a wire and cable manufacturing firm. But alas my technical knowledge is limited at best. Although the magic of osmosis is a wonderful thing. Where can I go to get an education in such matters as these?

Sounds like you had an interesting career! Well, there are couple of ways do go about gaining knowledge, but the best is usually just diving in. As I told Jim above, the forum over at http://diyaudioprojects.com/ is a great place to start. The forum is excellent and there’s also a fair number of project pages with projects for all skill levels and experience.

Are you interested in building, designing, or both? People over on the forum can suggest some first projects to get you started once you decide what you’d like to tackle first. I also have some links to some text books on tube design if you are interested in learning how to do design. Do you currently have any knowledge of electrical principles? If you think you could use an introduction or refresher, I can suggest some texts for that as well. Welcome aboard. It’s a great hobby.

i want to build a vacuum tube amp and a vacuum tube preamp for my stereo system (NAD integrated amp/pre amp with a Rotel phono amp). i don’t know quite where to begin, so i am networking to learn about kits, books and to get advice. my system is in my garage and i like to listen to jazz when i putz on projects. i am retired and 70ish and smart enough to learn. thank you you for any advice. sincerely – jim

Jim;

I’m always glad to help. The best suggestion I can make is to get involved with the forum over at http://diyaudioprojects.com/Forum/. If you post your question there myself and the other regulars can help guide you. I will say that the limiting factors are really your skill set and how much you want to spend. There are some bottom up designs that are very good (this 6V6 amp for example) as well as some good kits. I look forward to hearing from you on the forum.

Matt