While dealing with my other spring chores, I’ve been working to get the finish applied to the amplifier’s top plate. While not perfect, I believe it is acceptable enough for me to proceed.

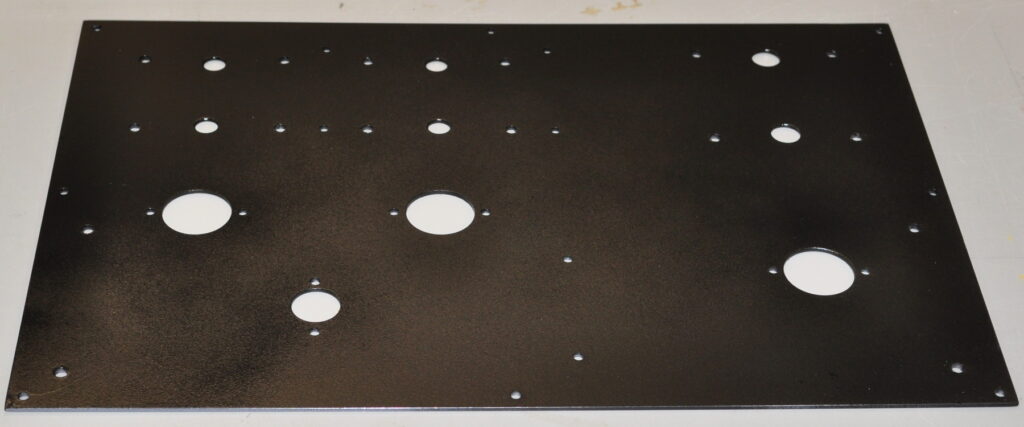

The travails of applying modern spray paint aside, I believe I have succeeded in getting a finish I can live with. It’s not as smooth as I generally like, but with everything mounted to the top plate, it should have a nice overall appearance. Here’s the top plate after about twenty hours of dry time.

In this picture, it picks up some glare from the LED lights in my shop, but in more normal ambient light it looks pretty good. Now I have to be patient.

Past experience has taught me that when using modern spray paints sold in the US, they really don’t cure properly for an extended period of time. I think that with some care, I should be able to get most of the items mounted to the plate after five or six days of curing. So assembly should start next weekend. But I will still be exceedingly careful with the finish for at least a month.

It feels good to get the final chassis construction complete. Now it’s all about building the amplifier itself. I’m really looking forward to getting this project well underway.

As always, questions and comments are welcome.

Matt,

Have you ever considered powder coating. Here in the Philly PA area we have several powder coat piece at a time job shops. Costs a few bucks, but is a very professional finish, way better than I have ever done with a spray can. What about your Front Panel Express guys – send them your drawing file they send back a ready to go top plate.

I thought about FPE but for a top like this it’s about $100 USD. It would be nice to have all the drilling/milling done as well but that’s still a fair amount of money for a retired guy. There is a powder coat shop just down the road from me but for single pieces like this it was still about $50 USD. Better than FPE but still a fairly stiff fee just to avoid the spray paint.

It’s one of those jobs that I always wrestle with but, but in the end, I usually end up just doing it myself.

Looks good Matt. I know what you mean about modern paint. I’ve learned what works best for me. I went to the Rustoleum website and found that the enamel paint can be baked on up to 350 degrees. I spray the plate with a heavy coat of paint, no primer, onto the metal. Set it level in an electric oven that is not preheated. Set bake temp to 275 or so. After about 15 minutes turn oven off and let cool overnight without opening. Paint self levels, cures very hard and is very chip resistant. Of course this is not the stove we cook on. Just thought I would pass this on for anyone who might be interested.

Can’t wait for the next progress report