Back in June, in the Competing Priorities post when talking about the 6AS7 SET, I made the following statement:

I also had another idea this morning which may lead to a little more prototyping work to check out a theory I have (another potential delay). But if the experiment turns out well, I may move bias points around a little on the 6AS7.

Well, I spent this morning with some prototype circuits and a stack of tubes investigating the bias points for the 6AS7 SET power stage. And I learned a couple of important lessons.

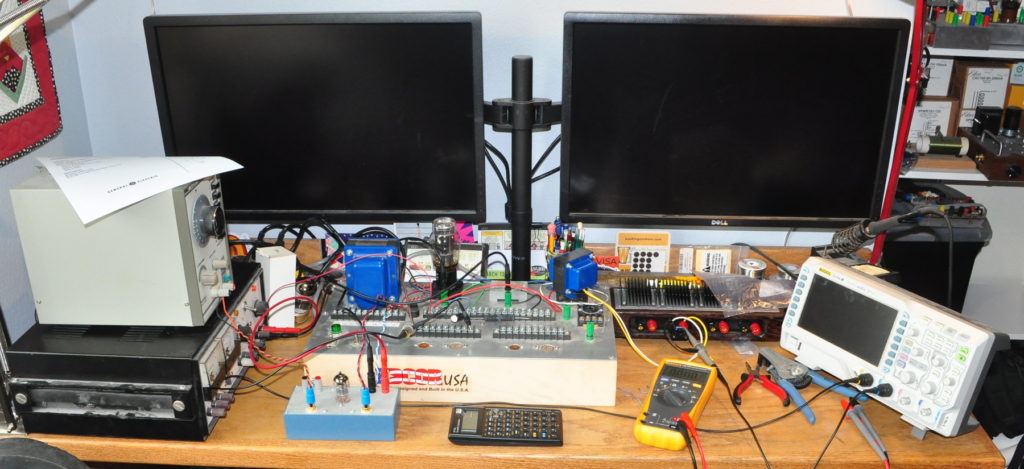

First, here is a picture of my setup just after I finished work this morning.

I had some issues with the setup simply because of the “inverted” B+ power scheme for this amp. Usually in my amp designs the power stage is designed for the highest B+ voltage. However, in this amp the signal stage needs about 300v B+ and the power stage is down around 270v B+. And those 30 volts make a significant difference in the operation of the driver. I only have one regulated high voltage power supply. And the supply on my protoboard was not helpful. So I had to make some adjustments while setting voltages and taking data.

But most importantly, I learned (or at least was reminded) that I usually do things for a reason. This amp was originally designed in the spring of 2017 after completing my 6336 SET amp. When I was looking at the bias points back in June and reviewing what I chose in 2017, it seemed to me that I had been far too conservative in choosing the power stage bias point. At the chosen bias point (176.5v, 66.5mA) the plate dissipation is almost 10% below the rated plate dissipation. I usually design my amps closer to the limit to improve distortion performance. I had written no notes in my working notebook about why I had chosen this bias point and it left me wondering.

So this morning I put the circuit together and began experimenting. I used a number of different 6AS7 and 6080 tubes and it was then that I remembered what I had done and, most importantly, why.

The 6AS7/6080 is not an audio tube. It was designed and produced as a pass element for high voltage regulated power supplies. Now these supplies all tend to have a similar topology. In general, there is a pass element after the primary ripply filter, fed by a high gain error amplifier referenced to a cold cathode voltage reference tube. This is a classic feedback control system. Among its characteristics are high stability (if properly designed) and an inherent insensitivity to part variations. This means that the characteristics of the pass element can vary widely, and the error amplifier in conjunction with the high accuracy voltage reference simply correct for the variations. This means that the characteristics of the pass elements do not need to be held to tight tolerances during the manufacturing process. This increases production yield, reduces costs, and potentially increases profits for tube manufacturers.

While I was working with different tubes this morning (two 6080s, and four different 6AS7 tubes) I realized (again) just how significant this tube-to-tube variation can be for these tubes. I had chosen the bias point I did, because I had recognized this variability and designed such that if I or anyone else happened upon a variant (or “bogie”) tube, they would not end up red-plating the tube in the amplifier. This hold back sacrifices only about 1dB in the final output power so I thought it was entirely reasonable adjustment.

So I have again verified the bias point I settled on back in 2017 and learned two important lessons. First, I do things for a reason. I should try to remember this when reviewing older designs. Second, I really need to keep better notes in my working notebook about not just what I did, but why.

Now it’s time to clean up my mess and get back to work. I should have more progress to report on soon.

Thanks for re-checking—your well considered approach is appreciated. In all projects I guess we have to be agile and able to adapt the design in response to further information.

It seems that prototyping is a process where you make mistakes. The joke is that in this case, the mistake was thinking that you made a mistake : ) I am looking forward to seeing this amp get built.