After many delays I have finally finished the 6L6 SE-UL chassis. The paint is still soft but I should get started mounting parts in a week or so, as soon and the paint hardens appropriately.

The top is still not perfect. In fact it’s far from perfect. But I have decided that it’s acceptable and I need to move forward. Here is the chassis with the painted top plate set in place.

Some of the imperfections can be seen in this picture. In fact, the specular light from my shop lighting makes the imperfections look worse than they really are. When I get everything mounted and in position, I don’t think they’ll be very noticeable. I also made a very interesting discovery considering my spray painting technique. But that discovery is for another post.

Look for much more assembly news in the next few weeks.

As always, questions and comments are welcome.

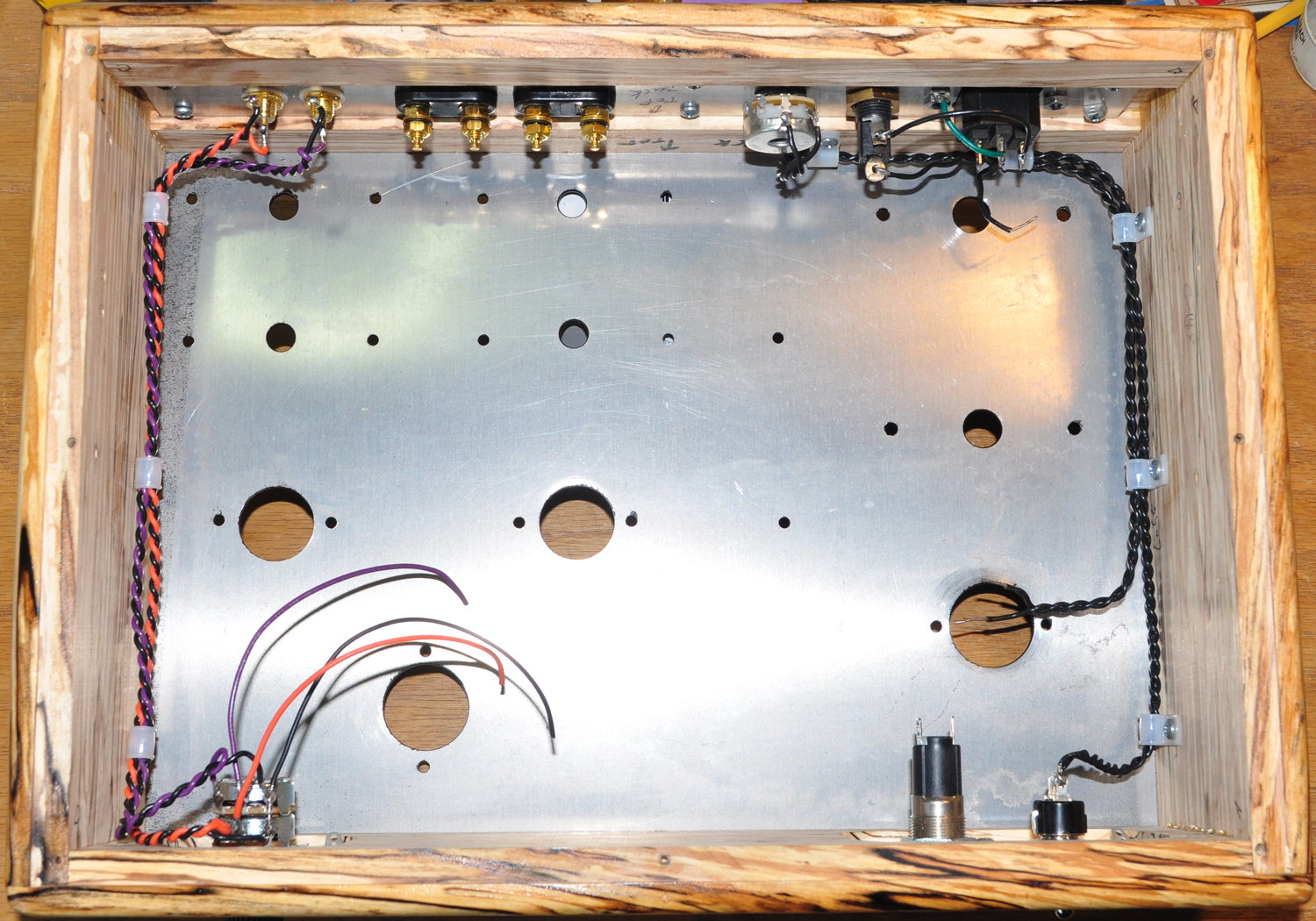

Can you post a picture of the inside? I’m curious about the metal side panels and how the connectors will be mounted. Your idea may have just provided a great solution for a project I’m considering.

The metal side plates are held to the inside of the chassis with 3/8″ #6 sheet metal screws. Here is a view of the inside of the chassis. My plates are inset by 1/4″ into the 3/4″ thick sides so the connectors, knobs, etc don’t sit too far below the outside surface.

My plates are inset by 1/4″ into the 3/4″ thick sides so the connectors, knobs, etc don’t sit too far below the outside surface.

Excellent. Nice work. I’m going to do a similar prototype for my project. Where do you get the sheet metal for the top and sides? Are they aluminum or steel?

The metal is 80 mil (0.080″) thick 6061-T6 aluminum sheet. I usually just get this from one of my local metal suppliers. You can also get this from places like “Online Metals” (whom I do use on occasion) but you then have to pay for shipping which drives up the price.

Hi Matt,

I think you will be extremely pleased when you complete your build and give it a listen. I’ve been listening to mine for about two months now and continue to be impressed. I’m not good with superlatives, but I can say that it has a full and very rich sound. I contemplated trying KT88 tubes, but I don’t think they would produce any meaningful increase in power output, the 6L6GC’s already sound fantastic, and, of course, the KT’s are more than twice the price of the 6L6GC’s! EL34’s seem interesting

Anyway, thanks again for a great design!

Now that I’ve finished the chassis and decided to move forward I’m eager to get to the assembly and testing phase of this project.

Unfortunately there are still a few outdoor jobs that are eating up a lot of my time (we’re having an unusually dry October here in the Pacific Northwest). But I intend to at least get to assembly as soon as the paint hardens enough to prevent scratching during assembly.

The imperfections appear as “dust”?

To be honest, this looks as good or better than most of my efforts. I trained myself to be a reluctant imperfectionist some time ago. Not that I’m devout in my practice though…..to my wife’s detriment.

This looks great to me!