Since I’m still waiting for appropriate weather to finish the 6AS7 SET chassis, I’ve been making progress on a small project for the aluminum chassis from the last post. I decided to put together the “Color” preamp from the post a few days ago. This project will make use of one of the Hammond discount power transformers about which I posted a couple of weeks ago. It’s coming along well, but VERY slowly.

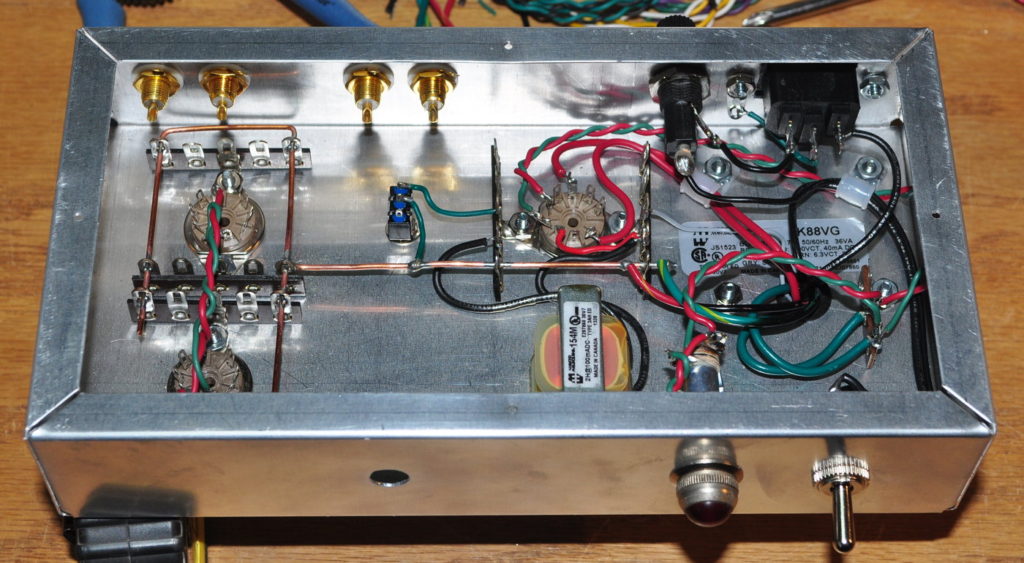

Frankly, I had forgotten how much I dislike working inside a cramped chassis. Lately I’ve been doing most of the assembly on my amps working with the flat aluminum plates. It’s a dream compared to having to work inside a project box. Here’s how far I’ve gotten on the preamp project.

I have installed all the parts on the chassis except for the volume control. It will arrive in a few days. I’ve wired in a ground lift switch. The transformer primary circuit is complete. The filament and lamp wiring is all completed as well. I’ve wired the rectifier socket and the main filter choke is wired in. A few filter caps, a dropping resistor, and a bleeder resistor and the main power supply will be complete.

When the project is complete, I’ll write up a full project page with all the information and test results for the preamp. Hopefully, in a week or two, the weather will begin changing and I’ll be able to make some progress on the SET chassis. Till then, I’ll be working on bringing this project to life.

As always, questions and comments are welcome. Honestly… I really mean it. Drop me a note… let me know what you think… really.

Since you offered, I have a couple of questions:

Where did you order the volume control from? Is this where you sourced most of the other parts?

You like 6v rectifiers, but did not mention the 6AX5GT in your diyaudioprojects page. It takes more heater current than the 6CA4, but do you have any other feelings?

I know this project uses a 6K88VG, but have you thought about designing a 12AU7 preamp from a 12v or 24v DC power supply?

Thanks for the blog; it is my favorite one to read,

Dan

The volume control for this project was sourced from Mouser Electronics. Most of the other parts came from my supply closet. Although I did also need to order the 1.0µf film capacitors as I didn’t have any that large on my supply shelf. They were sourced from Mouser as well.

I have not used the 6AX5 or 6AX6 rectifiers in any projects. The 6AX5 uses more filament power than the 6AC4, has lower current supply capacity, has significantly higher rectifier loss, and is an octal base. In almost all circumstances I prefer the 6AC4. I also prefer the 6BW4 to the 6AX5 although they are less well known. The 6AX6 is a high power rectifier suitable for large amplifier projects (originally designed for damper service) but it is also hard to come by (especially for reasonable prices) in most instances. I view these two rectifiers more as curiosities at this point in time. I did almost use a 6X4/EZ90 in this preamp project. It is a small 7-pin miniature 6.3 volt full-wave rectifier that excels in low current draw projects such as preamps and the like. But when I got around to considering it, I had already drilled the chassis for a 3/4″ hole for the 9-pin rectifier socket.

The only issue with designing a preamp running the 12AU7 (or any 12A*7 tube) with a 12.6v filament voltage is what to do with the rectifier. I could use a 25v supply, going with a 25Z6 rectifier and then use a dropping resistor for the 12AU7 filament, or use a 12.6 volt supply and a 6X4 rectifier with a dropping resistor for the rectifier. Neither option is particularly appealing in my mind. I solidly detest solid state rectification in tube circuits (however this is just due to my own personal intransigence) so I would likely never take that short cut. As such, the entire concept leaves me in a pickle, so to speak.

I am glad that you like my blog. I do try to keep it interesting.