A while back in this post, “6L6 SE-UL Primed for Progress“, I mentioned that I would no longer be painting the exposed bottom plates of projects which won’t be seen. What that statement actually meant was that I would be leaving the aluminum in a bare “as delivered” finish. Or maybe with just a little steel wool polishing. But I’m now modifying that stance slightly.

Almost exclusively I use an alloy of aluminum called 6061-T6. The actual formulation is not important except to say that I like the machining characteristics of this particular metal. However, the “as delivered” surface finish of this metal is just average. It typically possesses a lightly polished surface that has a tendency oxidize unevenly and take fingerprint smudges. Smudges that remain conspicuous even with buffing. Normally I would say that this is not an issue with bottom plates and other unseen surfaces. However, on those occasions when I do see these surfaces, they always strike me as having an “unfinished” look to them. This bothers me.

Recently when I was struggling with my spray paint issues I was stripping the top plate to reapply a new coating. As part of this process, I took the last of the paint off using a random orbit sander with a sheet of 320 grit sand paper. Surprisingly the result was actually a very handsome brushed aluminum finish. Further I noticed that, even with repeated handling, this plate did not tend to pick up fingerprint smudges and uneven oxidization patterns.

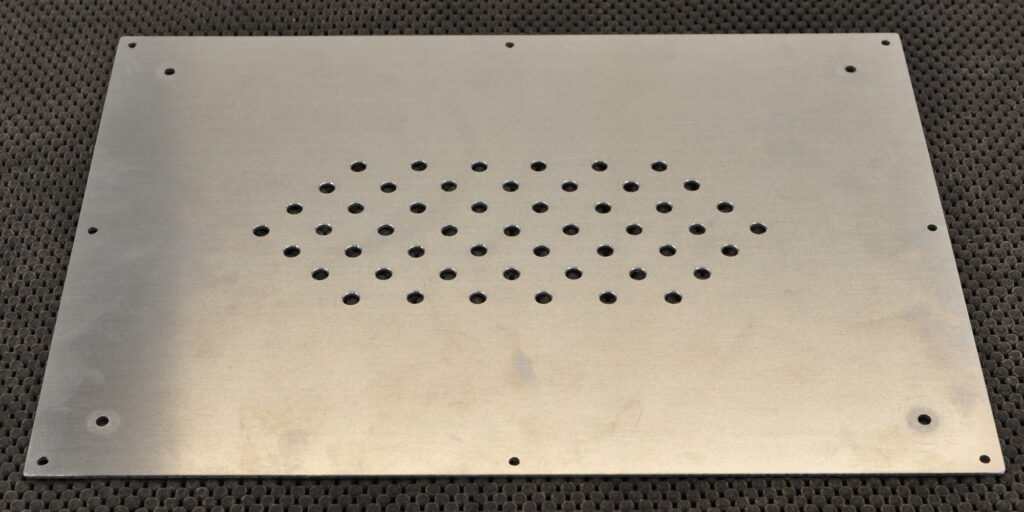

For the bottom plate of the 6L6 SE-UL I decided to try an experiment. This is a picture of the bottom plate in the raw finish as delivered from my metal supplier. It has been buffed lightly with 000 steel wool following machining but has no other surface preparation or finish.

This plate doesn’t look bad necessarily, however it does have an unfinished look to it. In this picture the smudges and uneven nature of the finish is really in evidence.

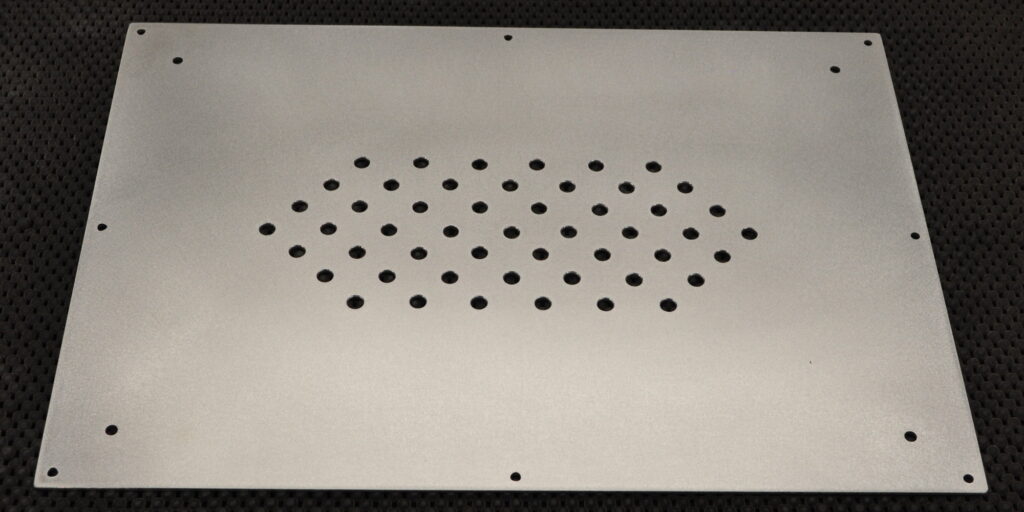

So I put a new 320 grit sanding disk on the random orbit sander and applied an even buffing to the entire base plate. Here is how it looks after the buffing.

This finish is much more even and it takes handling much better. The best part is that it only took a few minutes to do it.

The truth is that I like this buffed finish so much that I am tempted to try it on the top plate of an amplifier project. Maybe with a nice dark wood for accent. Some people may say that I’m being overly particular concerning a surface most people will never see. However, I feel it is details like this that make a project really come together.

As always, questions and comments are welcome.

I do something like this on seen surfaces. Only difference is the grit…..400. You’re right that it takes on a brushed finish look and fingerprints don’t happen as easily. I can often get away with decal application as well.