I have the initial set of data with the power supply prototype using the Edcor XPWR011 power transformer. It is enlightening and clearly shows which amplifier I need to build next.

I talked about waffling on the next amp project back in December. The reason was that I wasn’t sure that the 800VCT secondary of the XPWR011 was sufficient to produce the B+ needed for the triode strapped KT88 design I had in mind. This meant that I might instead finally build the triode strapped 807 amplifier for which I purchased this transformer almost ten years ago.

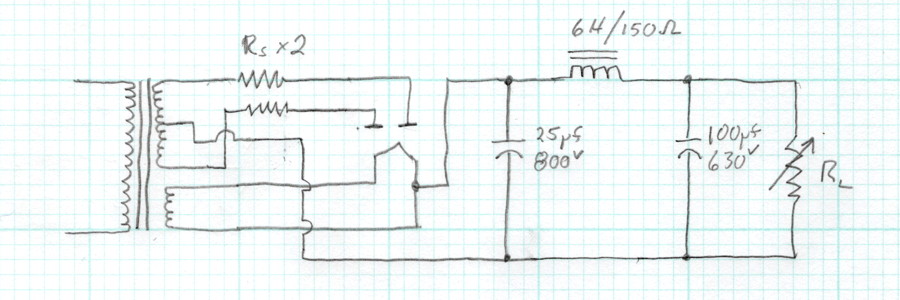

To help me make this decision, I decided to build a prototype supply which would allow me to test the transformer’s capabilities with a couple of different rectifier tubes. Here is the simple schematic of that prototype.

This is just a simple supply with a reservoir capacitor and a single stage of LC filtering. This is sufficient to characterize the DC performance with a couple of different rectifier tubes. The observant among us will notice that I’ve included two components in this supply which I generally omit; series plate resistors between the transformer secondary and the rectifier tubes. There’s a good reason.

Rectifier tubes require a minimum series resistance in each plate feed to function properly. Without sufficient resistance the tubes can arc between plate and cathode during the short conduction period. As the secondary voltage increases the required resistance increases as well. The reason that I usually don’t include these resistors is that the secondary winding of the transformer has a natural resistance dependent on the actual primary and secondary winding resistances and the turns ratio of the transformer. At lower transformer secondary voltages, this resistance is generally sufficient to ensure proper rectifier functioning. So although I do check, the additional resistors are usually not included in my designs.

As it turns out, the high voltage secondary on the XPWR011 has an effective resistance in each leg of ≈38Ω. A quick check of the data sheets for the 5U4GB and the GZ34 shows that this is not sufficient for the operation of these tubes at this voltage (i.e. 800VCT or 400V per plate). According to the 5U4GB data sheet, the required resistance is 52Ω. And according to the GZ34 data sheet, the required resistance is 125Ω. Clearly I needed to add some resistance in the plate leads to protect these rectifier tubes in operation with this transformer.

For the 5U4GB I decided to use 22Ω resistors. In addition to the inherent winding resistance this yields a total of 60Ω which provides a little margin (≈15%) over the design point. However, for the GZ34 the resistance needed to be much greater. For this tube I settled on 100Ω resistors giving a total of 138Ω with a little margin (≈10%). This would also allow me to compare the operation of the 5U4GB with both levels of resistance installed. I wanted to do this because I knew that the 807 design would require some dropping resistance in the final design anyway. If I use 100Ω in that amp it will protect the rectifier in case a GZ34 is installed by mistake.

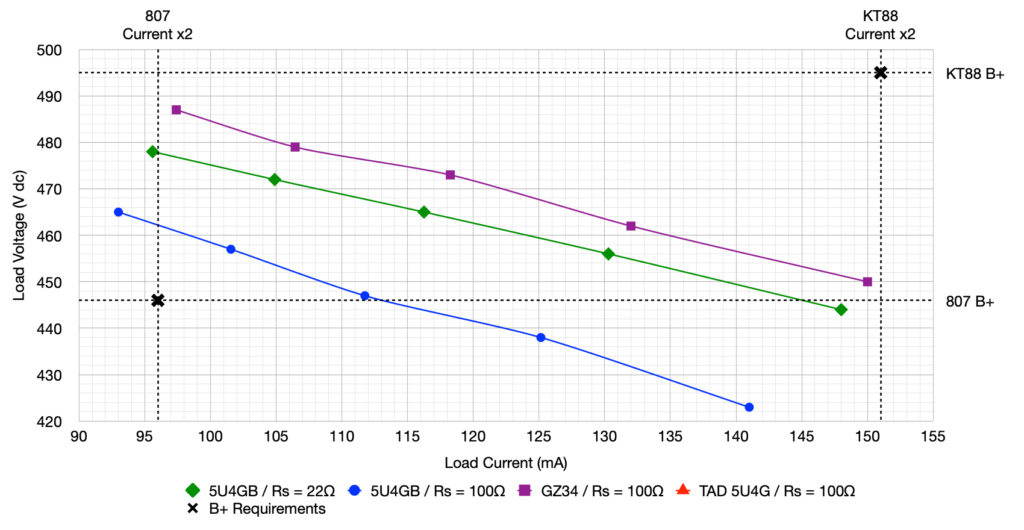

Here is the data for the two rectifiers and two configurations.

Each line in the graph shows how the power supply voltage changes as the current load on the supply is increased. The data points were taken at fixed load resistances of 5.0kΩ, 4.5kΩ, 4.0kΩ, 3.5kΩ, and 3.0kΩ with load resistance decreasing as load current increases. I have also included the B+ requirements (for both voltage and current) for the two different amplifier configurations. The two amplifiers have B+ voltage requirements that only differ by about 50V. However, the current requirements are wildly different. The top line (in purple) represents the GZ34. The next line down (in green) is the 5U4GB with 22Ω Rs resistors installed. The third line (in blue) is the 5U4GB again but with the 100Ω Rs resistors installed.

It should be evident now why I said that this data clearly shows the path forward. At the current level required by the 807 amplifier, all three configurations provide ample B+ voltage. However, at the current level required by the KT88 amplifier even the GZ34 solution is about 50V too low. Clearly the XPWR011 transformer is not well suited to my KT88 design. It will however work very well with my 807 design. As such, I think that will be the next amplifier to get built. I have some unique ideas for the chassis for this amplifier but details of that will have to wait.

For anyone disappointed that I’m not going directly to the triode strapped KT88 build, please don’t despair. After looking over the data last night, and since I’ve already received the output transformers for the KT88 amplifier, I went ahead and ordered the Edcor XPWR077 – 900V@200mA CT, 6.3V@5A, & 5V@3A CT power transformer. The additional 50v-rms per plate should get me very close to the B+ requirements for that amp. The XPWR077 is the highest voltage power transformer in the standard Edcor product line. If I want anything higher voltage I’ll either have to have one custom wound by Edcor or go with a Hammond 700 series transformer.

Now that my decision has been made it’s time to get moving with the chassis design. As I hinted before, this chassis is going to be different from anything I’ve ever built before.

As always, questions and comments are welcome.

Pingback: Yup. More Testing | Cascade Tubes

Hello Matt:

Thanks for posting the data. I am a little confused and perhaps you can help me understand what is happening here. I am thinking that you have used the two dependent variables as the axis for the graph, with the independent variable as the curve being presented. I am not familiar with this way of presenting data. Do the curves change if you put the independent variables on the X axis?

The max voltage for the 807 is significantly less than the potential of this transformer. Are you going to generate a lot of wasted heat bringing the voltage down to your target level?

I really like your test rig. I do the same thing when working out a power supply design.

To give you the simple answer on the graph, you are correct. Strictly speaking, the independent variable is the load resistance. Thats why I said “… load resistances of 5.0kΩ, 4.5kΩ, 4.0kΩ, 3.5kΩ, and 3.0kΩ …”. These load resistances are shown by the points highlighted on each line. However, the resistance I used to get a V/I point response from the supply is really immaterial. What I am interested in is how the voltage changes as a function of the current drawn from the supply. Technically these are plots of power supply sag. I could have done two curves for each case, one for voltage and one for current, each plotted against the load resistance. But then the relationship would not have been nearly as clear.

Remember that for an 800V center tapped secondary in two diode, full wave rectification, the absolute maximum DC voltage is (800v/2)*1.41≈565v minus the rectifier loss and the loss in the load resistors in the two secondary legs. As you can see from the plot, the voltages are not that excessive for a target B+ of 446v. As for the 807 voltages, the max plate voltage in triode mode is 400v. The stage is cathode biased and the bias is about 38v. The output transformer DC loss is about 8v. That’s why the 807 voltage requirement line is at 446v. Depending on the rectifier configuration I use I will have to reduce the B+ by between 16v and 42v. But there will also be some loss in the channel dependent smoothing filters. And I would like to minimize the amount of heat I’m dumping with a power supply dropping resistor.

Does this answer your questions?

Well Thank you very much Matt:

That was a very understandable answer. I suspected you were after PS sag. I also now realize you would have presented additional sets of graphs and ended at this summarization graph.

I had not realized how much sag there would be on a PS. I suspect the slope of the sag curve is transformer dependent, based on current demand and availability (as the slope appears constant on the graph). Therefore, different transformers will show differing slopes on the sag curve. Which will have a direct effect on the performance of the amp and temp the transformer operates at.

Thanks again for the discussion

Quick early question;

How are you going to run the 807?

Triode connected

UL

Dare I say pentode

One thing I see on the data sheets is that the screen grid max voltage rating is considerably lower than the max plate voltage rating – how will this come into play?

My personal experience with the 807 was in old pp pa amplifier output stages. Also saw a few as class c rf finals in small cw transmitters.

The power stage will be run in triode mode with an 800Ω cathode bias resistor. I show some initial data from this configuration in this post. Needless to say, the cathode will be appropriately bypassed.

According to the specification sheets, the maximum plate voltage (and consequently screen voltage) in triode mode is 400V. Now generally this type of limit is based on the PP configuration where the power dissipation increases with drive signal. This limit tends to prevent screen burnout and red plating in high drive conditions. But in Class-A SE the peak plate and screen power dissipations are at zero signal. So if the conditions are acceptable at zero signal (which they appear to be in the prototype) then I’ll run the tube with 400V on the plate and let it be.

But now that I’m thinking about it, I may modify the prototype jig to include some sense resistors for the plate and screen, then check absolute power dissipations. I may be able to increase the voltage above the 400v limit. It will be an interesting experiment.

Thanks for jogging my brain. 🙂

Thanks for the new posts! Glad there is clear data for an informed decision – Looking forward to seeing the new chassis design.